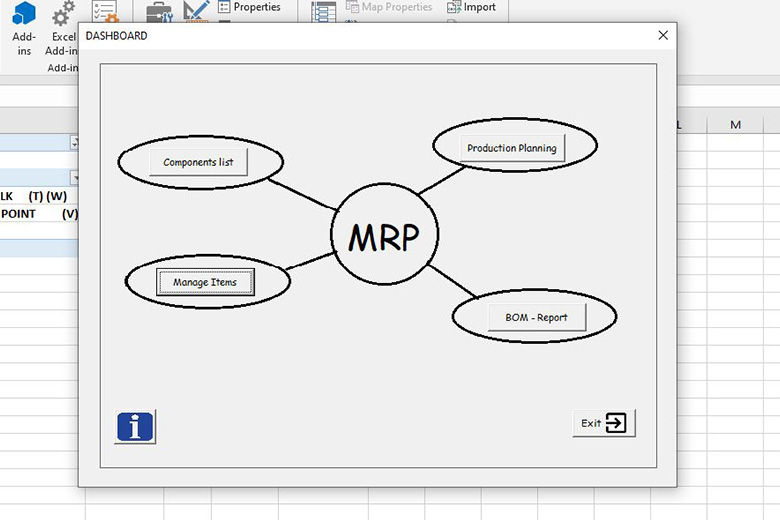

Material Requirements Planning (MRP) is a system for calculating the components needed to manufacture a product. Every final product has a recipe with one or more components and quantities.

The primary objective of MRP is to make sure that materials and components are available when needed in the production process and that manufacturing takes place on schedule.

Better Production

improve manufacturing efficiency by using accurate production planning and scheduling to optimize the use of labor, equipment and components.

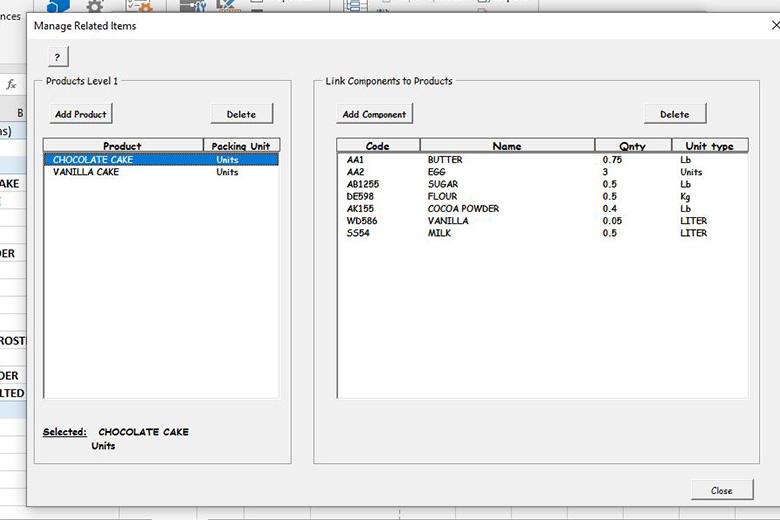

Bill of Materials

The bill of materials (BOM) specifies the relationship between the end product (independent demand) and the components (dependent demand). MRP takes as input the information contained in the BOM.

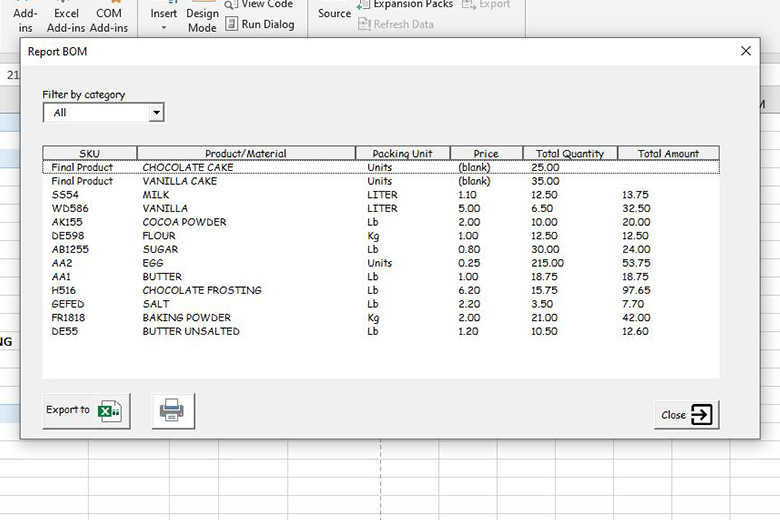

Reports

With this report you won’t run out of stock and won’t overstock components.

It shows the total quantity of components that you will need to produce your final products.

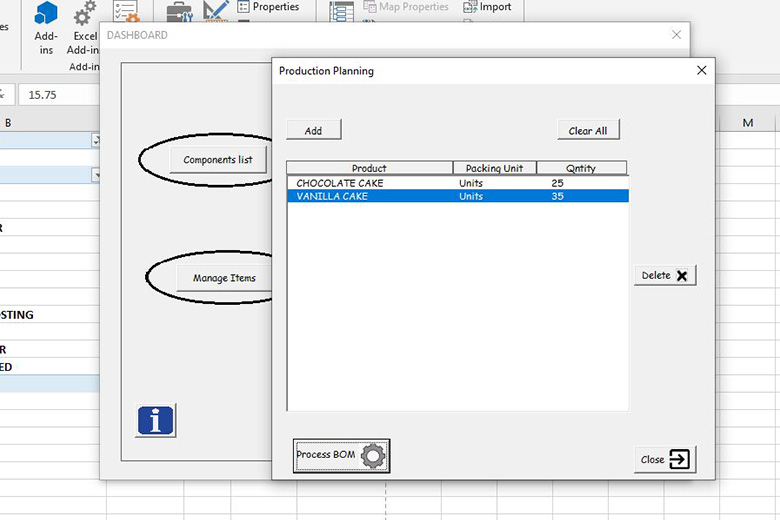

The three key questions that you must ask when planning for dependent demand are:

- What components do we need?

- How many of each component do we need?

- When do we need the components?